Popular polypropylene

Polypropylene (PP), a highly crystalline thermoplastic polymer, is produced by the chain growth polymerisation of propylene, a gas obtained from petroleum cracking. PP can be produced with different molecular chain structures under controlled conditions (stereo-specific) but only the ‘isotactic’ form, in which the methyl side groups are arranged on the same side of the polymer chain, is produced in large quantities. More information on polypropelene: https://en.wikipedia.org/wiki/Polypropylene

The history of man-made fibres began at the end of the 19th century with the first semi-synthetic or regenerated materials (van Oosten 2002) and although completely synthetic polymers were developed in the early 20th century, many fibres that are now in common use were not fully exploited until the 1960s and 1970s.

IIsotactic polypropylene was successful from the early 1960s due to the new catalysts for polymerisation developed by Ziegler and Natta in 1954 (Brydson 1999). It became an important plastic being used in many different forms and applications through a range of manufacturing processes. A large proportion of PP is used in fibres as constituents of fabrics, upholstery and carpets. Many industrial uses involve ropes, woven and non-woven fabrics and reinforcements. For more information on rope and how to braid it see the following:

Chemical and physical properties of polypropylene

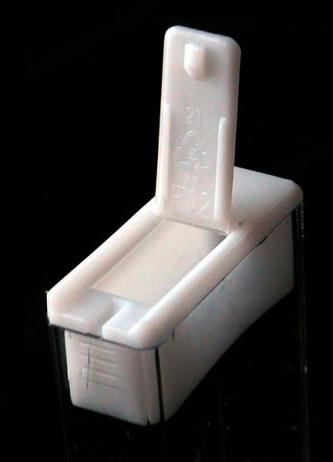

Several different polymerisation methods can be used to produce PP, but all rely on exposing the propylene monomer to high temperatures and pressures in the presence of an active metal catalyst. By selecting particular catalysts and polymerisation methods, the molecular configuration of the polymer can be directed to one of three forms: atactic, isotactic or syndiotactic. The images here show the monomer and polymer structure of PP and three types of PP.

Atactic polymers are characterised by their tacky texture, amorphous behaviour and low molecular weights. Where present they act as a plasticiser by reducing the overall crystallinity of the PP. From a commercial viewpoint, isotactic PP is the most important form of the polymer. In comparison to the atactic and syndiotactic forms, isotactic PP has the greatest degree of stereo-regularity; as a result, a higher degree of crystallinity is achieved. Many of the mechanical properties and processing characteristics of pp are determined by the level of isotacticity and thus crystallinity.

The useful properties of the polymer, combined with its comparatively low price, make it suitable for a wide range of applications. PP is the lightest of all man-made fibres (0.91 g/cm3) and has the lowest moisture absorption. Dirt will not penetrate the fibre and can easily be removed from the surface. Polypropylene fibres have the same tensile strength, wet or dry, and are also highly resistant to both acids and alkalis and to most organic solvents. The fibre does not rot and is not readily attacked by micro-organisms or moulds.

BACK TO TOP

Production process

Most PP fibres are made by extruding the liquid material through the holes of a die plate, followed by spinning and stretching. The slit film method, however, in which the polymer is extruded through a small slit, was also used from the start of pp production. Slit film tape yarns were used principally in carpet backing and industrial sackings. Fibrillated yarns were developed in the 1970s. Nowadays, PP can be found as monofilaments, split or slit films, as either multifilament or staple forms. The polymer is usually pigmented before extrusion. More information on extrusion: http://en.wikipedia.org/wiki/Plastics_extrusion

Degradation of polypropelene

Since the 1980s the production, consumption and applications of this polymer have increased through the application of even more efficient catalysts and property enhancements and today PP is the most common fibre used all over the world.The usefulness of polypropylene depends on the retention of its useful properties during a prolonged service life. Under mild conditions, unstabilised PP will retain these qualities for long periods of time. In most applications, however, exposure to heat and light will occur, accelerating oxidative degradation that results in a decrease in elastic properties, loss of flexibility, development of surface cracks and discoloration. For details on the degradation of polypropylene see the Chemistry & Physics section. The properties that make PP widely used as a fibre do not prevent the fibre from deteriorating over time when exposed to daylight and UV radiation (Lemaire et al. 1988).

These images show clear signs of degradation; brittle and loose fibres on Fête 1.

- Brydson, J.A. (1999) Plastics Materials, 6th edn. London: Butterworth Heinemann.

- Lemaire, J., Arnaud, R. and Lacoste, J. (1988) ‘The prediction of the long-term photoageing of solid polymers’, Acta Polymerica 39(1/2).